Decoration techniques

SCREEN PRINTING

The screen printing technique comes from the 17th century from the stencil printing method used

in the Far East mainly by the Japanese and is considered to be the creator of screen printing

Yuzensai Miyasaki. The screen printing method was originally used to decorate kimonos,

patterns were cut out on paper and applied to a grid stretched over a wooden frame

human or animal hair, An interesting fact is that the Fiji islands stencils that they were needed for printing fabrics, they were made from perforated banana leaves.

The first breakthrough was Samuel Simon's use of 1907 in

Great Britain matrix made of silk cloth, partially covered with varnish

instead of a stencil calling the technique "Silk-Screen". Improvements that have been made

to this method have made the screen printing technique popular all over the world over time

world.

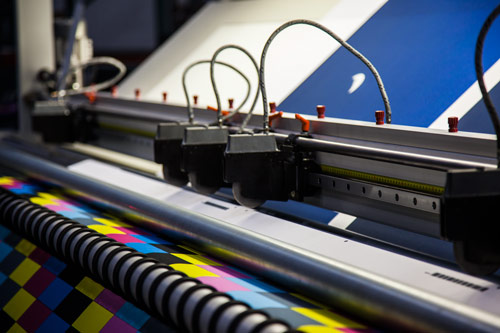

A very fine polyester, nylon or nylon fabric is stretched over an aluminum, rectangular frame

metal net. The main parameter characterizing the sieve is the number of interlacings

mesh fibers per square centimeter, which in practice means the number of holes

through which the paint will be pressed at a later stage. A whole sieve prepared in this way

it is covered with a photosensitive emulsion that tightly plugs all the holes in the sieve.

The next step is to prepare the cliché. That is, a print on transparent foil

the negative of the pattern that we will print – each color of our project is a separate one

plate.

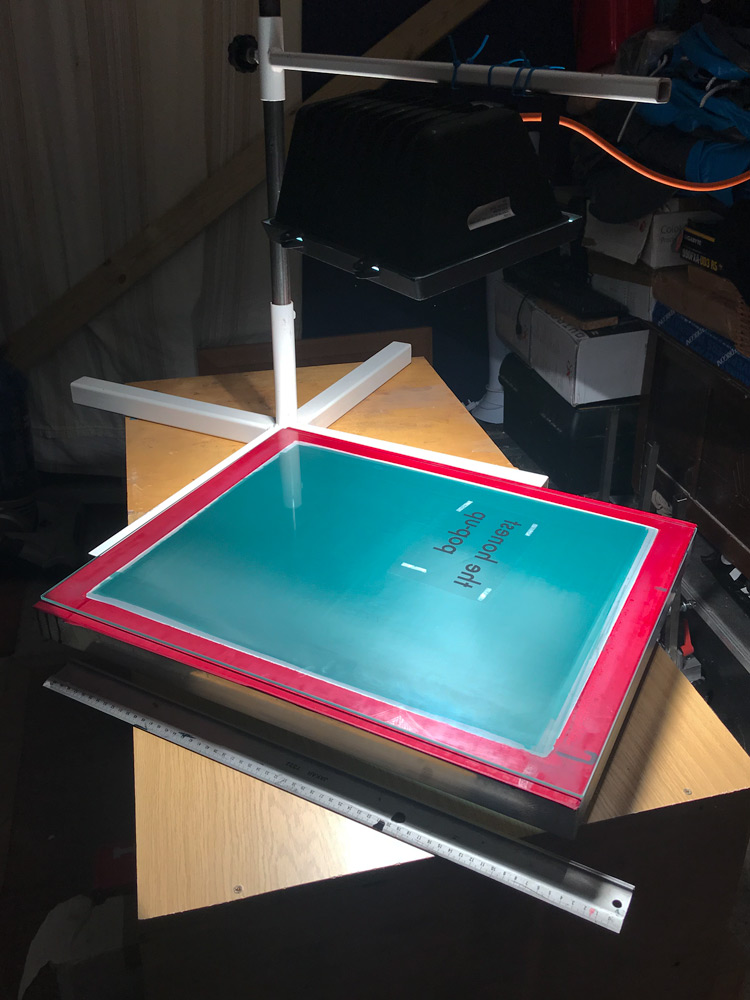

The set prepared in this way goes to the platesetter, which fixes the emulsion by emitting light

photosensitive only in places to which it has access. The rest is covered with a printed film

is not fixed, and after rinsing with water under high pressure, it causes complete

removing the unfixed emulsion that was covered by the printed film. As a result, on

holes remain only in the places indicated by us. The above process

is repeated for each color of the printed pattern.

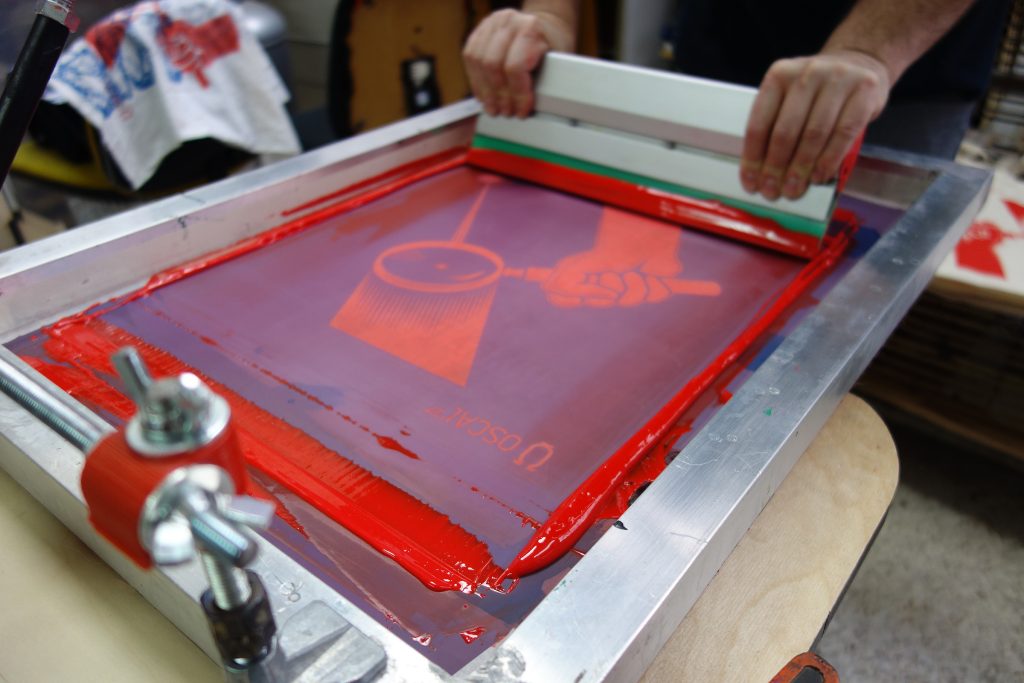

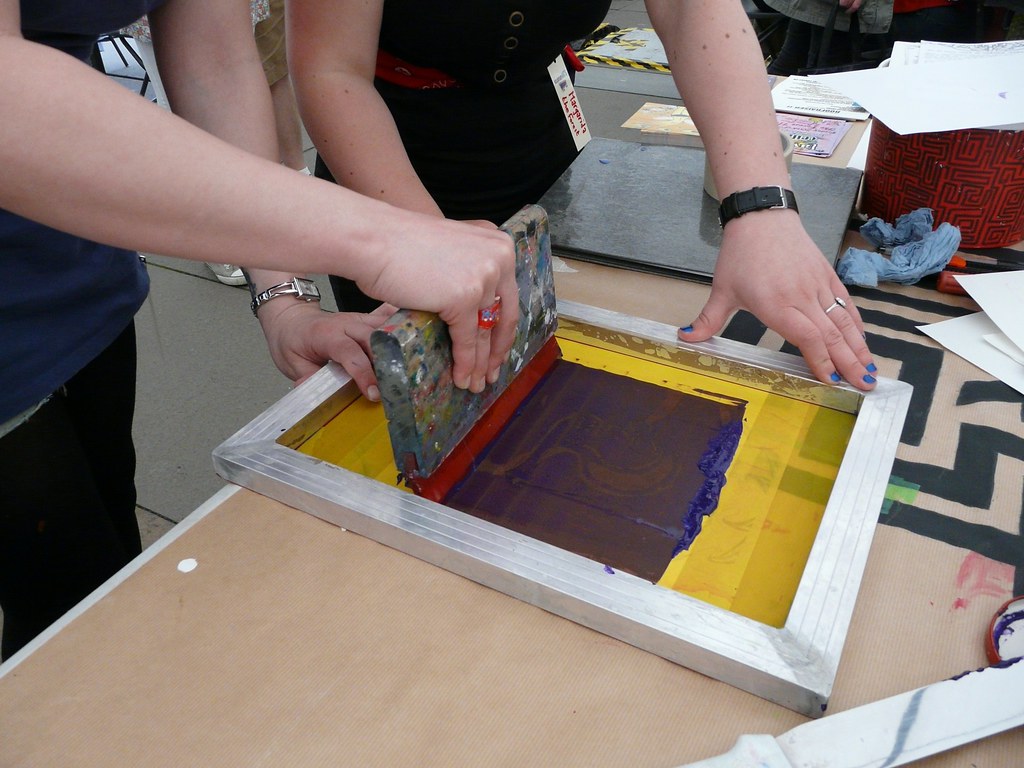

Before the last stage is the printing by placing it on the machine

screen printing screen covered with paint, which is squeezed through the holes in the squeegee

sieve and thus hits the material in the right place.

Finally, the printed material is heat treated for the purpose

paint fixation. This is done in specially adapted belt furnaces in

high temperatures.

In screen printing on textiles, we use three types of inks:

– water paints,

– solvent,

– plastisol.

Through the use of a wide range of different types of screen printing inks, in addition to

ordinary, flat prints, you can also achieve special effects in the form of: gel, HD, swelling, glitter, reflective or fluorescent prints.

We use screen printing to decorate knitwear, such as t-shirts, polo shirts, sweatshirts, sweatpants,

tank tops, long sleeves). Screen printing is a durable method of printing on clothing, it is cost-effective

usually with higher production volumes. The strong side of screen printing is durability and

saturated colors, complex graphics, special effects.

SUBLIMATION

Sublimation is the transition from a solid to a gaseous state with a direct bypass of the state

liquid. In practice, it is a transfer of a pattern printed on sublimation paper

on the material under the influence of high temperature. Dried on sublimation paper

the paint becomes volatile under the influence of temperature and permanently colors the material,

on which it is placed. The pattern applied to the fabric is very durable and indestructible.

The only downside of sublimation is the ability to use this technique only on

knitted fabrics and polyester fabrics. It is the polyester fibers that have the property that

subjected to high temperature, they allow penetration into their interior

dyes contained in sublimation inks.

Due to the specificity of printed materials, sublimation is used in decoration

a wide range of sportswear and various gadgets. High-quality

materials are characterized by excellent thermal insulation properties and

breathing. In practice, it is the cheapest and simplest process of decorating textiles. from this

For this reason, it is especially recommended even for small orders.

The process begins with the preparation of graphics, then printing on the printer

sublimation, and then we heat the pattern onto the material in a specially prepared calender

possibly presses that operate at high temperatures.

The strength of sublimation printing is its durable, photographic quality

intricate patterns.

COMPUTER EMBROIDERY

Embroidery is one of the oldest techniques of decorating clothing. The oldest, documented

examples of embroidery come from the turn of the 5th and 4th centuries BC. and have been discovered by

archaeologists

in present-day Greece. This technique consists in hand stitching patterns on fabric with a needle and thread. The milestones for embroidery were: the invention

embroidery hoop (beginning of the 18th century) and the construction of the first embroidery machine in

1990

1828.

Computer embroidery is classic embroidery with thread, specially for this purpose

dedicated embroidery machine. It is computer-controlled, which allows for unusual

fast work using several threads of different colors at the same time. She takes advantage of

a special pattern designed in an embroidery program.

In order for the pattern to be created, a digitizing program, i.e. arranging, is used for this purpose

stitches based on a given graphic or logo. The task of the designer is to arrange

stitches so that the embroidery machine can understand them and embroider them

intended effect. Therefore, the person preparing the project plays an important role in the process

graphic preparation.

Embroidery is a very durable method of marking clothes, it guarantees high quality of workmanship a

it is also not damaged by frequent use and repeated washing. By

embroidery, we can achieve unusual effects thanks to the threads available on the market

fluorescent, reflective, metallizing as well as a 3D effect using a special one

foam.

DTF

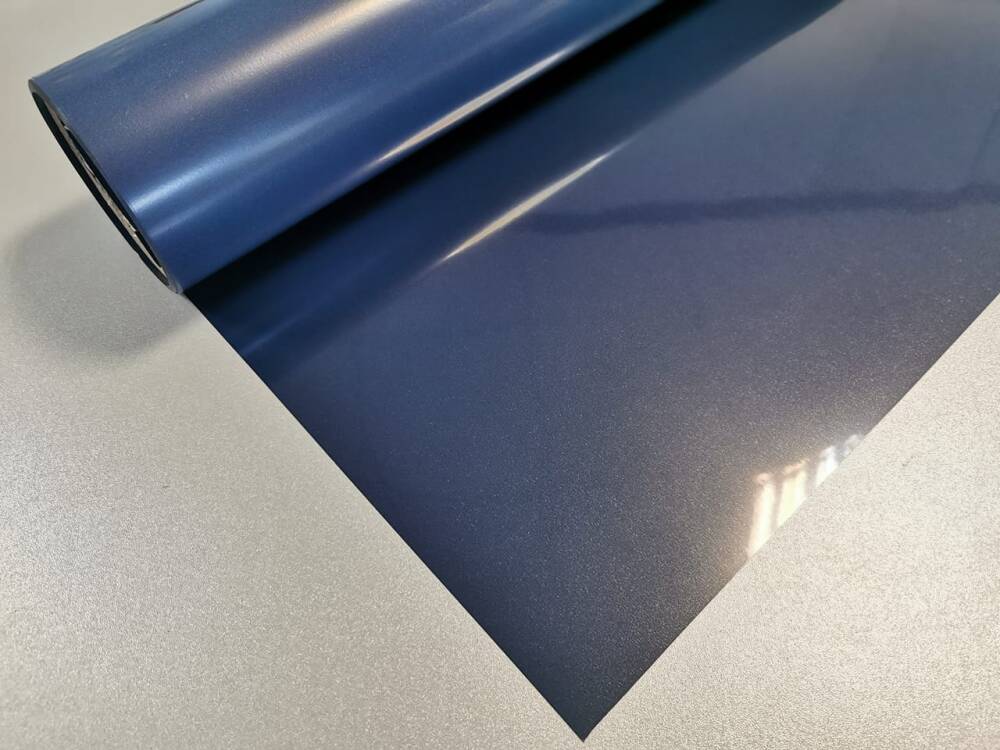

DTF – Direct-to-film – one of the latest techniques of decorating textiles, means

method of applying ink to the foil intended for this technique, using glue

fabric transfer, also used in screen printing, and applying the prepared one

printing on a textile substrate using a transfer press.

DTF is an innovative method of digital printing that is gaining popularity every day.

DTF eliminates all problems and difficulties resulting from printing directly on

textiles, while maintaining excellent quality and color gradation. DTF printing method

combines the digital quality of the print and the durability of screen printing.

The print is made on DTF foil, which allows you to reduce the amount of used

ink. Then the printed foil is sprinkled with a special glue

thermoactive. Overprint, z

applied glue, must be dried using a tunnel or a thermal transfer press, as a result, the glue bonds to the ink. A properly dried product is a transfer

ready for application to the fabric. The resulting print is of high quality and

durability.

Perfect for small, personalized orders or decorations

various elements in different places of the product that can be printed on

one sheet of foil. Unlike DTG printing, textiles do not require prior printing

pretreatment coverage, and the print is less sensitive to the quality of the cotton it is against

applied.

DTF also gives the possibility of application on various types of materials. Prepared print,

can be transferred to various products, e.g. hats, t-shirts, bags, scarves, etc. In addition,

DTF transfer can be cheaper than DTG printing – the more uses on the sheet

we print, the lower the unit cost of the final product.

Pros of DTF printing:

– high quality and the ability to print with color gradations

– high print durability

– low costs with short series and printouts of many elements on one sheet

– the possibility of preparing many elements (different patterns) for

fast transfer when executing individual orders

– does not require prior pre-treatment of the substrate

– the possibility of applying the print on various materials

Cons of DTFs:

– higher costs for large orders

– limitation of air permeability

– no possibility to obtain special effects on the print as in the case of screen printing

DTF Limitations:

Limitations of DTF printing may result from high costs, in the case of large ones

orders. The prepared print is limited due to the use of glue for thermal transfer air permeability.

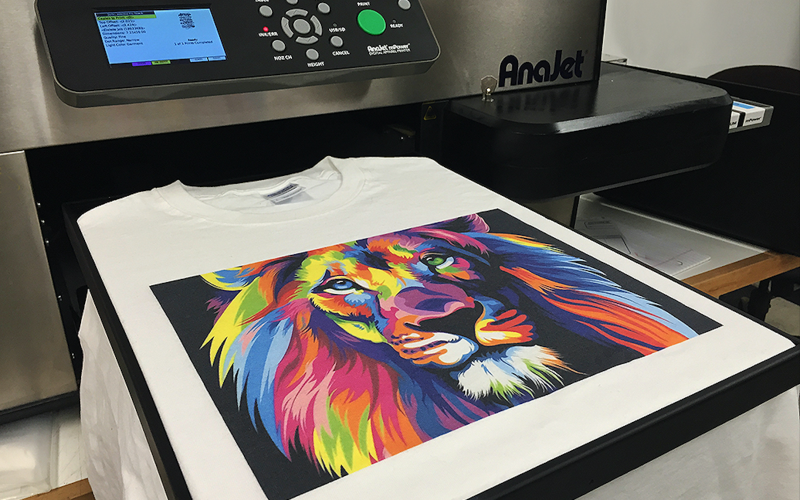

DTG

DTG – Direct-to-garmet – means direct printing on a cotton substrate or on

a mixture with a predominance of natural fibers. The print is made in a DTG printer, ink

penetrates the structure of the fabric, reproducing the appropriate graphics. The print is fixed by heating in a thermal transfer press.

DTG, as an innovation, was established several years ago and is one of the printing technologies

digital, consisting in printing directly on the substrate. Initially

used on light cotton substrates, developed over time and currently allows

wider application, also on dark substrates, as well as on mixed products

composition.

The absolute advantage of DTG printing is the accurate and precise rendering of depth and transitions

tonal colors, thanks to which the print is clear, saturated, effective, and at the same time

very durable. An additional advantage of the application made with the use of DTG printing is

permeability – the printed material breathes. DTG printing, unlike printing

digital DTF, does not use glue that fixes the print on the selected material. Yes

the prepared print is light, practically imperceptible on white fabrics.

Unfortunately, it is different in the case of printing on dark fabrics, here the structure of the print is w

in most cases will be detectable, due to the so-called white color overprint,

which on the one hand will emphasize the colors of the graphics, but on the other hand will be an

additional layer

stiffening. DTG printing is characterized by high resistance to washing –

comparable to the high quality and durability of screen printing.

First of all, when we want to put full-color graphics on the fabric. DTG technology allows us to print almost

photographic pictures on the material

accuracy. The price of the print is affected by the amount of ink used, which depends on the print itself

graphics and their size. What else is very important? DTG digital printing is already paying off for us

with 1 piece of print. Why? Because we do not bear the costs associated with such

preparation as required by screen printing. In addition, the undoubted advantage of DTG is time

printing, in the case of digital printing, it usually takes only a few minutes. DTG printing

it also works in accordance with the zero-waste philosophy, minimizes stocks of materials, has

positive impact on the environment.

Pluses of DTG:

– high print quality

– high print durability

– very good color reproduction with tonal transitions

– a light print that can breathe – on light substrates

– short printing time

Minuses of DTG:

– high costs for large series in relation to screen printing, resulting from wear

inks and the cost of servicing the operator executing the order

– perceptible printing on dark materials

– no possibility to obtain special effects on the print

FLOCK AND FLEX FOIL

WHAT ARE FLEX AND FLOCK FOILS?

Flock and Flex are specially prepared and used foils for clothing decoration

and materials. Using foil, you can create t-shirts, sweatshirts, hats, kidneys and much more,

many other products with your own imprint.

HOW DO WE PREPARE PRINTING WITH FOIL?

It all starts with a properly prepared project in vector graphics.

Imprints made using foil are one-color or two-color, without transitions

tonal between colors. There is also a limitation with this technique of decorating clothing

detail size. A properly prepared design is cut out on the foil in reflection

mirror. Using a blade or a special selector, the cut design is removed

unnecessary elements to obtain a print according to the prepared design. Then cut out

the foil print is placed on the garment and is welded into the material with

specialized thermal transfer presses. Heating takes place in high

temperatures appropriate for the selected type of film.

DIFFERENCES BETWEEN FLOCK AND FLEX FOIL

Flex foil is smooth to the touch. In turn, the Flock foil is a bit thicker, and because of it

structure, it resembles a delicate nap to the touch. Therefore, it is less flexible than

Flex foil. Despite the inability to make multi-colored prints with

gradients, clothing decorated in this way does not have to be boring at all. There is a wide range

color of these two films: glitter, luminescent, metallic, perforated and

many other. Films are ideal for marking sportswear, because

they are washable up to 80°C. Prints made using this method will present

also works great on T-Shirts, Polo shirts, waist packs, backpacks and bags and

polyester materials.